- Rent, Lease, or Purchase

- |

September 2, 2020

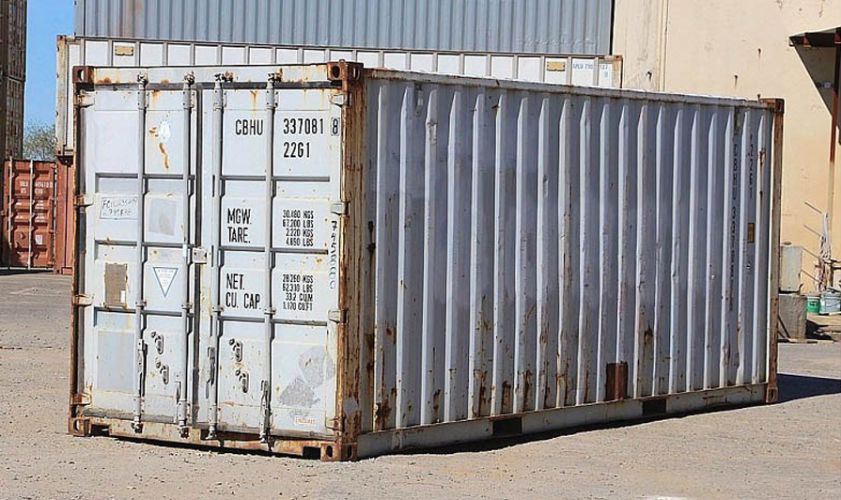

Rust on Shipping Containers – Inevitable but Preventable!

Storage shipping containers are not as indestructible as you might think.

Made of Corten steel, they are designed to sustain harsh environments. But, when the containers come in contact with both oxygen and water, an oxidation reaction occurs. This causes hydrated iron oxide to form, or rust.

If preventive measures are not taken once the rust is spotted, the situation could worsen quickly. Concentrating on strengthening resilience and reducing vulnerabilities to weather changes can help.

Why Do Shipping Containers Rust?

Corten steel is designed to be used in a cyclic environment to slow the rate of rust development. It must be subjected to both dry as well as wet environments. When dry, it’s at its most corrosion-resistant state due to the oxide layer that forms on top. Once wet, the layer gets destroyed and starts rusting. When back in the dry environment, the oxide layer rebuilds itself and becomes non-porous. The oxide layer on top is necessary to prevent oxidation. Despite this wet and dry cycle, rust can still creep in.

It mostly happens due to salt air, standing water on the container, or due to dents. Other factors that can contribute to a shortened container life are:

- Various corrosive elements like airborne salts

- Industrial pollutants

- Transport damage that results in breaching of the paint coating

- Constant exposure to the marine environment (i.e., saltwater spray)

- Salt-laden roads

When buying shipping containers, it is advisable to understand the maintenance requirements and ways to navigate through the challenges.

What Are the Different Types of Rust?

Watch out for structural (something that affects the integrity of the container) or non-structural (outer surface) rust. The non-structural rust hampers the appearance, which can be easily fixed. If your container has structural rust, meaning rust that is lying beneath the surface, it could interrupt your container shelf life.

Why Is Rust Prevention Important?

- Rust gives off a poor visual image.

- It can negatively affect the resale value, especially the minimal surface level rust.

- When rust starts to settle in, the corrosion that ensues can be extremely expensive to repair.

- It could be a hazardous issue for nearby residing people or anyone coming in contact with it once the rust gets to its worst state.

How Can You Prevent Rust from Aggravating?

- You can do regular checks for signs of any surface damage and corrosion of the protective layer.

- Moisture is the reigning enemy of steel; therefore, it is very important to keep it dry. All areas that collect water must be drained.

- Check the roof of the container to see if it is holding onto any residual water to help curb the rusting process.

- A lot of the water gets collected at the bottom of the container doors, so it’s essential to keep a check on that as well.

- Constantly inspect the dents, deformations, condensation and damage to the paint layer or metal structure.

- Keep a check on your container’s contact with high rainfall, humid subtropical climates and persistent fog that eventually creates droplets of water and salt-laden air.

Prevent Your Shipping Container from Condensation, A.K.A Container Rain

Because shipping containers are made of metal, internal temperatures often differ from the weather conditions outside. Once a container reaches its dew point, the moisture falls out of vapor into liquid form. This condensation causes molds, mildews, and corrosion. It also damages the cargo and its packaging. It is very important to know that the right amount of air space, ventilation, temperature control and moisture content in the goods can help contain the brown-red ugly patches on your containers. The number of times you plan on using the container could also affect the amount of wear and tear it sustains.

What Are the Methods You Can Adopt to Treat Rust?

Local Treatment

In the initial stage, you can wire brush the rusted areas and then finish it off with sandpaper. Vinegar can be rubbed on the affected areas and left to dry. You can also apply DTM (direct to metal) paint to cover the cleaned areas. Clean the stains with diluted Ospho and paint it over with a primer and topcoat.

Sandblasting

An expensive but proven method revolves around sandblasting, sealing and then painting the container. To achieve this, you have to go deep down into the bare metal up to a point where you can no longer see the rust to ensure that the container is 100% rust free.

Zinc Painting

Zinc paint has qualities of slowing down the growth of rust, so you can certainly go ahead and take on this cathodic approach. The zinc, when painted on the rusty areas, ensures electrical conductivity with the underlying steel. Quality zinc paint should contain at least 90% dry zinc powder. Alternately, you could bolt or weld zinc anodes in the hulls to prevent rusting.

What’s most important is to prevent structural rust. Once the structural integrity has been negatively affected, it will render the container unusable. Even though steel is certainly durable in its own right, it has the potential to corrode or disintegrate. Prevention is key and maintenance and regular inspection of storage shipping containers should be taken seriously.

If you notice any signs of rust on your rented or leased shipping container, call Mobile Modular Portable Storage at (866) 459-7600 or fill out our 'contact us' form, and our in-house field team will promptly assist you with repairs resulting from routine wear and tear of the container and equipment.

Related Blogs

Subscribe to Our Blog

Enter your email address to subscribe to the blog and receive the notification of new posts by email.

Thank You for Subscribing to Our Blog!

Stay tuned for upcoming emails with valuable content that we hope will enhance your experience with our brand.

Both Pardot and mg360 form submissions failed.